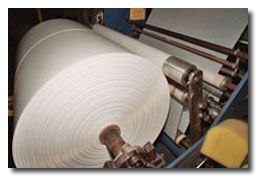

Substrate options, low extractables, when tacky is good.

Our silicone coating technology permits MTi to coat silicones onto direct-coated papers like SCK and CCK, or polycoated paper, PET, TPO, polyolefin, and non-woven substrates at high coating speeds and with extremely low extractables. We are capable of attaining extractable levels less then 1% on PP and PE films. This cure level is advanced for thermal silicone systems.

These low extractables allow our customer’s adhesives to perform their jobs without negative influences from migrating silicone. Using MTI’s highly-engineered release products, customers have achieved increases in tack levels with their standard adhesives. In some instances performance improvements of up to 33% were realized without any change to the psa chemistry.

Superior release performance

MTi’s technicians are experts at designing silicone chemistries for protecting and releasing all manner of pressure sensitive adhesives and mastic compounds at very high temperatures. This is especially important for roofing, building, and construction applications.

MTiPolyexe products are designed to meet and exceed even the most stringent specifications, maximizing operating efficiencies in your plant. Key characteristics like high temperature resistance, dimensional integrity/flatness, and caliper control, will result in measurable improvements in your manufacturing operations.

Release Liner Coating Highlights

-

Silicone coating for film, paper, and polycoated paper

-

Release chemistries for all pressure-sensitive adhesives and mastics

-

Extremely low extractible silicone systems